Moin from Hamburg!

Sustainability is a topic that not only concerns each and every one of us, it also affects all areas of our lives and work – including, and perhaps especially me, Tom, in my role as Head of Logistics. From transport routes to the various options for shipping and securing packages, the logistics industry has huge potential for development and is still largely in its infancy when it comes to sustainability.

That’s why my team and I have spent the last few months focusing on optimising our shipping processes and packaging materials. Where can we find smart alternatives to conventional methods? How can we make our work processes more energy-efficient? How can we restructure the premises in a clever way?

Here’s what we have achieved and implemented so far:

Brown rather than white

We will send our goods very soon only in brown instead of white boxes. Wondering how this helps the environment? Well, switching from bleached to untreated cardboard actually saves on important resources.

Custom grooves over filling material

Our new boxes also feature several optional folding edges. This allows us to fold our packages in a variety of ways, leaving less empty space inside the box and saving on both filling material and space when shipping.

Paper tape instead of plastic

Instead of conventional plastic adhesive tape, we now use wet adhesive tape made of paper. With this switch, we have achieved our first goal on the road to plastic-free packaging. What’s more, thanks to the significantly higher stability and stronger hold of wet adhesive tape, we use significantly less than the plastic packaging tape we were using before.

And we have many more plans in the pipeline, including the following:

Think bigger

We are currently working on enlarging our outgoing goods area so that, in future, we will have the space to store packaging material directly at the point of use. By removing the extra transportation step currently required to deliver this material as and when it’s needed, we will significantly reduce our energy consumption – and benefit from more time.

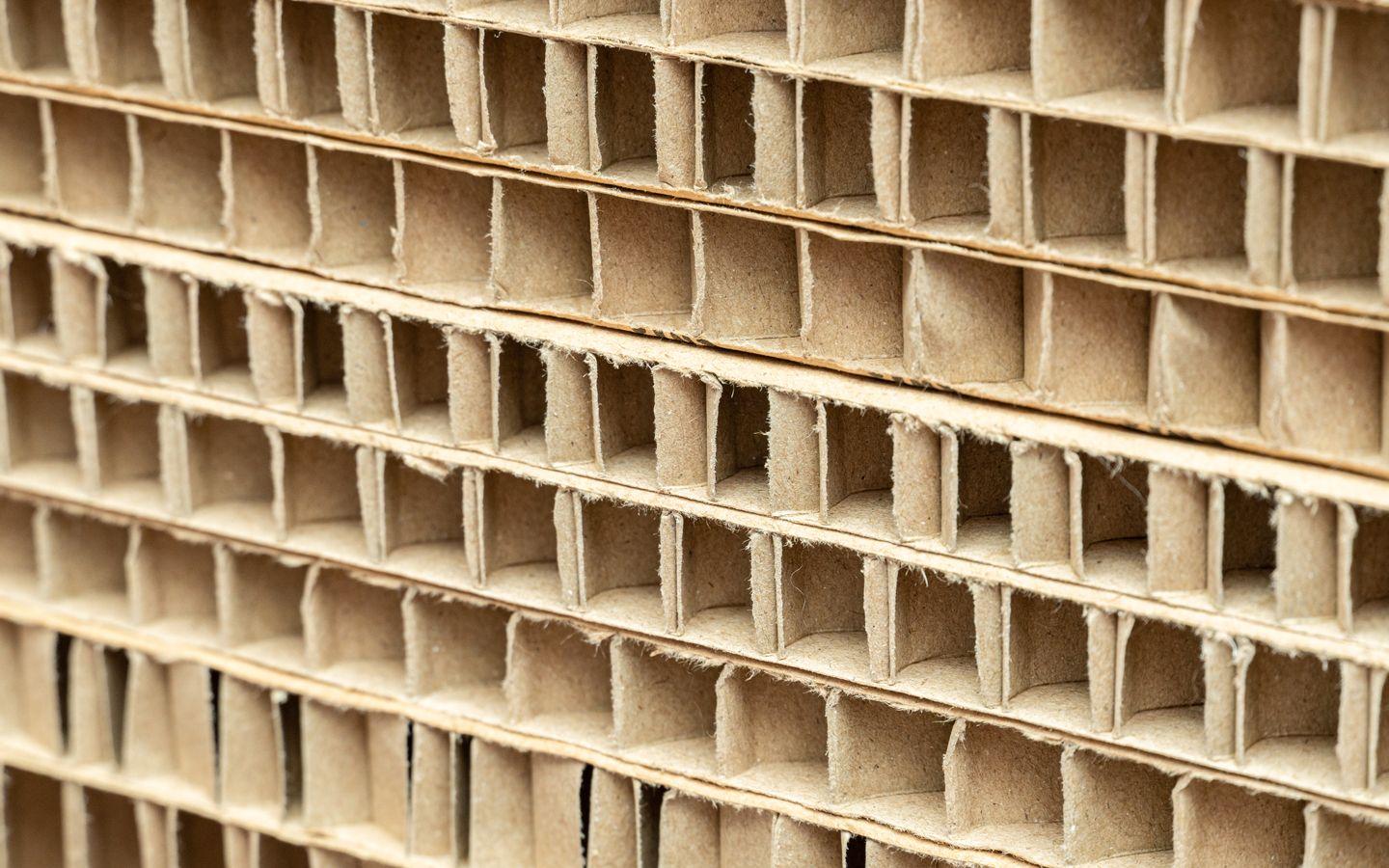

Helpful honeycomb

Over the course of spring 2022, approximately 80% of our goods (which represents a large proportion of our national shipments) will be shipped on so-called honeycomb pallets made of paper. In the medium term, we plan to do away with wooden pallets entirely.

Honeycomb pallets weigh 70% less than their wooden counterparts, which leads to a considerable reduction in CO2 during transportation. What’s more, these paper pallets are completely recyclable.

Well, that’s all from me for now – I’m sure you’ll be hearing more from the logistics team soon.

Best wishes,

Tom